Engineering Studies

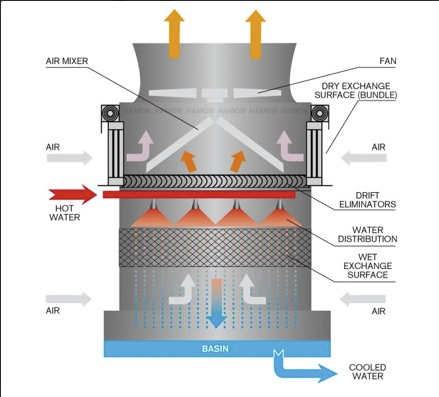

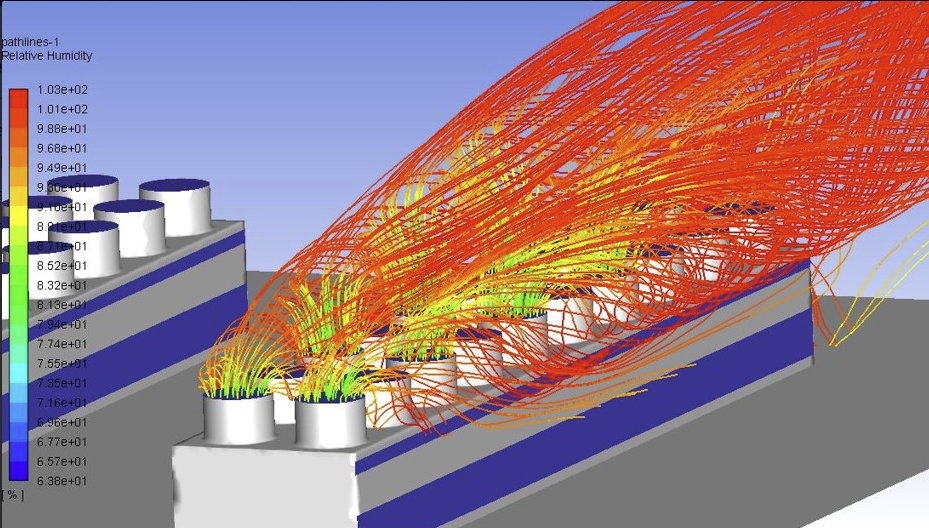

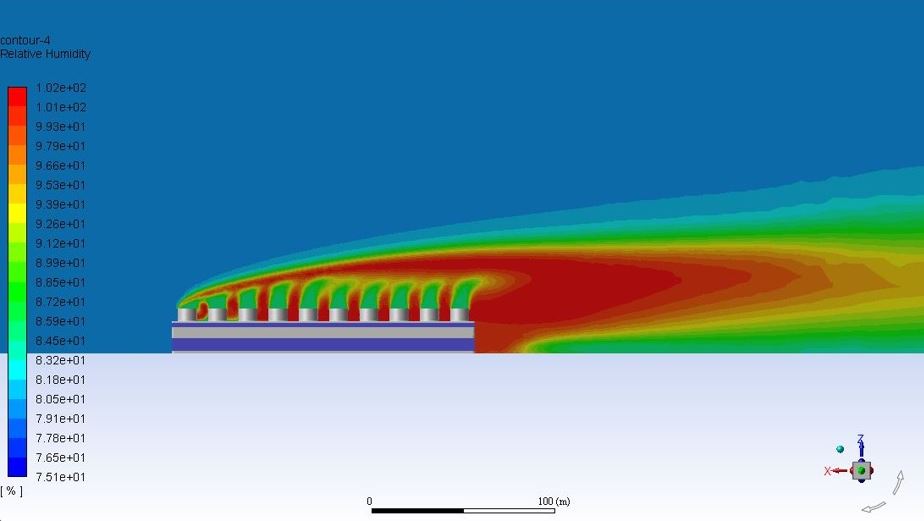

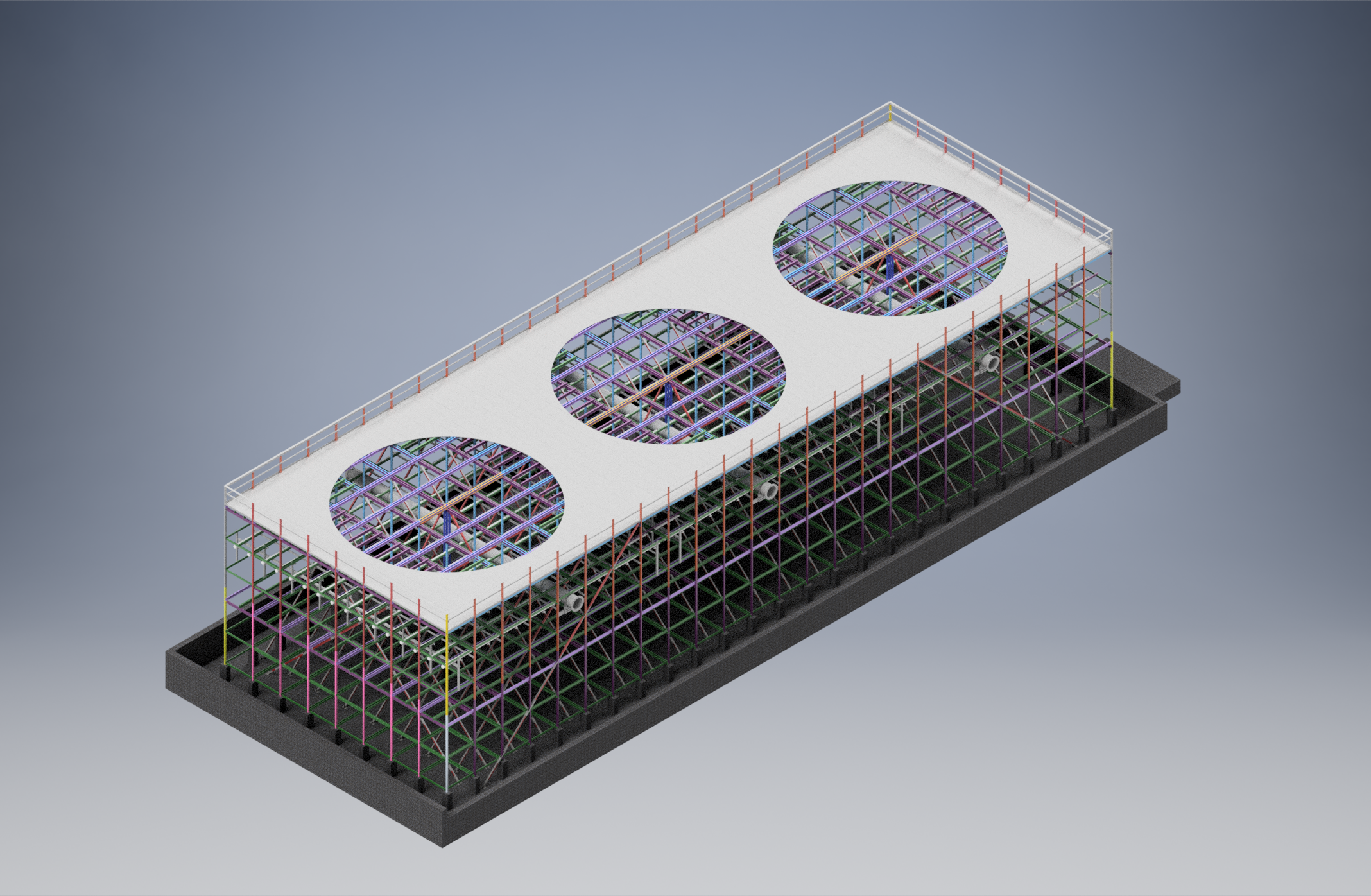

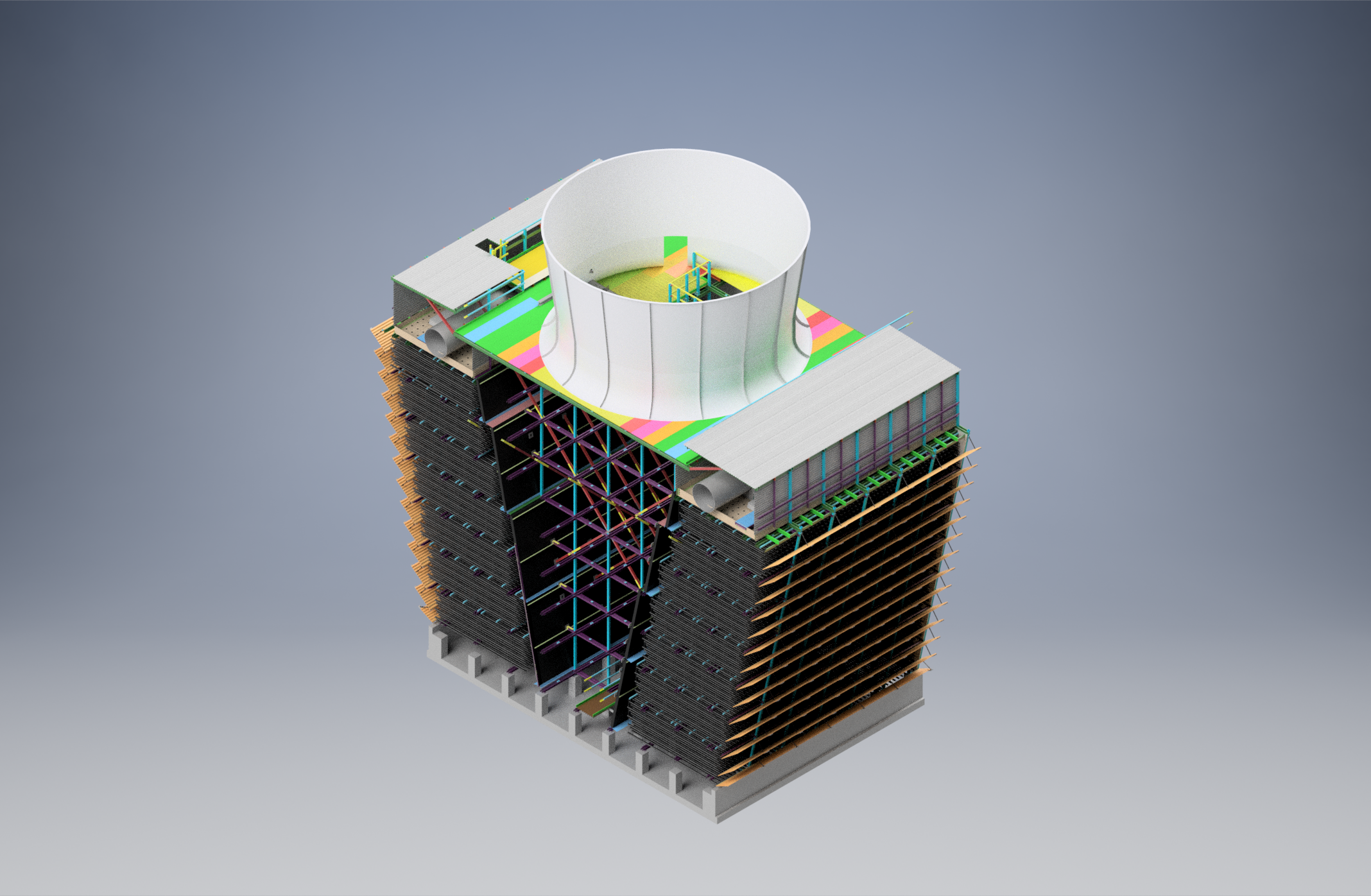

Our engineering team provides a wide range of services to our clients, from FEED study information and tower siting to Plume Studies using CFD modelling to Structural and Hydraulic computations as well as thermal modelling of the tower’s operation. Our clients benefit from our EPC level approach to engineering every project before design or construction begin, ensuring the tower will operate at maximum efficiency.

PLUME MODEL USING CFD

PLUME MODEL USING CFD

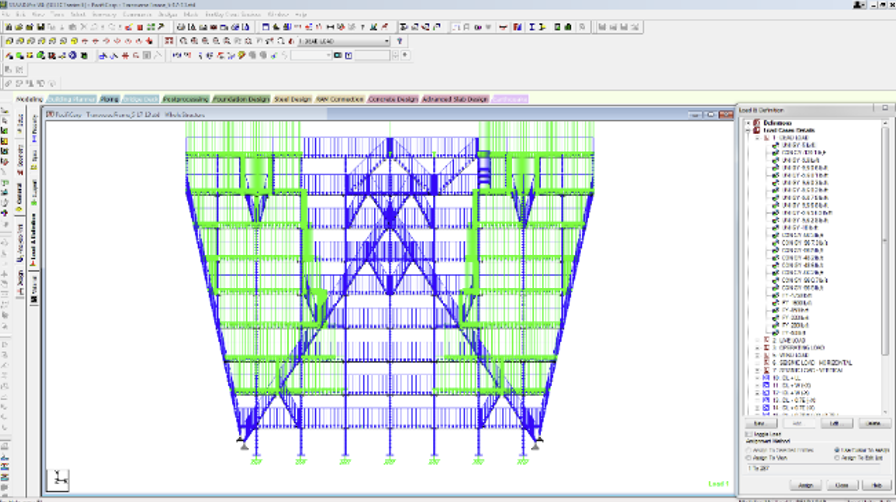

3D DESIGN WITH STRESS ANALYSIS

3D DESIGN WITH STRESS ANALYSIS

Design Build

Our new tower design utilizes state of the art structural, hydraulic, and thermal design models to optimize the tower offered. Optimizing tower design for constructability and future repairs are essential for many of our clients. Understanding the everchanging operating parameters regarding water usage, chemical usage and power consumption are all considerations when we design a cooling tower.

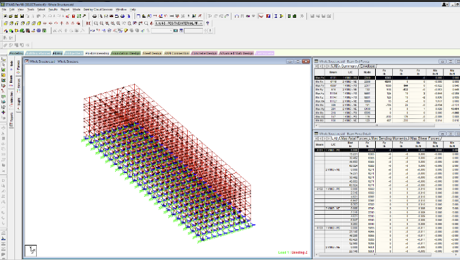

FEA MODELING

STAAD MODELING

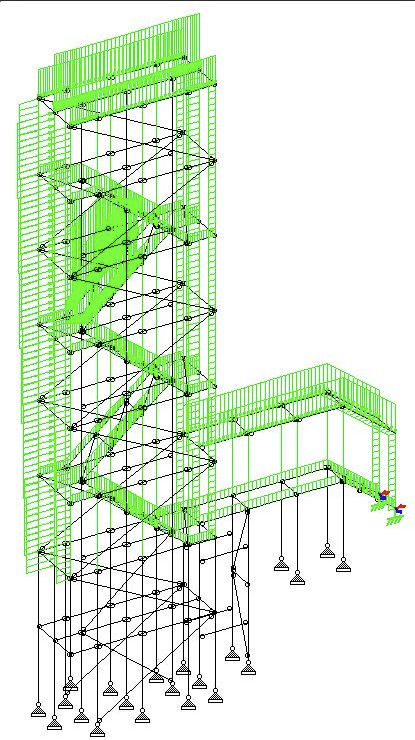

ICT STAIRWAY DESIGN MODEL

Aftermarket Replacement

Repair and replacement of cooling towers is one of our strengths. Having maintained many of our client’s towers from the day they were installed to the day the plant is decommissioned allows us to fully understand the life cycle of a cooling tower and its component replacement intervals. Our construction and engineering focus ensures we collaborate with our clients to make sure the latest technologies are considered when a tower is up for repair or replacement

We are originators of the wood to fiberglass repairs and replacement on existing cooling towers. Our first wood to fiberglass replacement was in 2000. With input from our field technicians, we have continually improved our construction techniques and methods.

CTI Committee’s

ICT has been active member of the CTI since 1985. We have presented papers and are on CTI committees to provide input into all aspects of our industry. We currently sit on or are involved in the following committee’s

- CTI Chapter 1 – Cooling Tower Operations

- CTI Chapter 4 – Winter Operations

- CTI Chapter 13 – Inspection of Cooling Tower

- CTI Standard – STD-114 Designs with Douglas Fir Lumber

- CTI Standard – STD-119 Timber Connection Specifications

- CTI Standard – STD-134 Plywood for Use in Cooling Towers

- CTI Standard – ESG-123 Concrete Restoration and Repairs

Research Grants

We have research partnerships with Texas A&M and the University of Alberta – two leading institutes where we explore and expand our knowledge on a variety of cooling tower related research topics:

- Thermal Modelling programs including CFD analysis

- Plume Abatement Designs

- Fill Performance Testing and Optimization

- Innovative Construction Techniques

Through our Partnership with San Jacinto College, we donated equipment for their Center for Petroleum Energy and Technology (CPET) for student training and education in the Petrochemical Industry.